This Engineer Left DJI to Help Hardware Startups Survive the 0–1 Phase

If your hardware idea is still on paper or halfway through a rough prototype, Carson Lin has a message for you:

“The most expensive problems in hardware aren’t in R&D or manufacturing. They’re in all the wrong assumptions made in between.”

Carson spent 7 years at Foxconn, Huawei, and DJI, working across the full NPI pipeline—from product definition and EVT/DVT builds to production ramp and post-launch support. Now based in Shenzhen and Dongguan, he runs a small technical supply chain team that specializes in the hardest part of the process: turning ideas into real, testable, buildable products.

Why Thinking About Mass Production Too Early Can Kill Your Hardware Product

Many founders think about production too early and validation too late. According to Carson, that’s where most hardware projects start to go sideways.

“We tell every client: if your EVT or DVT stage isn’t painful, you’re probably doing it wrong.”

He’s not exaggerating. Carson’s team spends most of their time catching problems that should’ve been discovered months earlier:

- Designs that skip DFM (Design for Manufacturing)

- Products with vague or incomplete reliability standards

- Early builds with no structured change log or review checkpoints

And when those problems only show up during tooling or mass production, the costs multiply.

What Successful Teams Do Differently

From the projects that went smoothly, Carson sees five key patterns:

1 They study how users actually use the product.

Not just what users want, but how they behave. “Use scenarios change everything,” he says. “People abuse hardware in ways you never expect.”

2 They treat EVT/DVT as failure-finding missions.

The goal isn’t just to build something—it’s to break it. Especially in reliability testing, Carson’s team pushes hard to simulate edge cases early.

3 They document everything.

Every design change. Every supplier tweak. Every BOM update. Without this, “a single missed update can create weeks of chaos.”

4 They pause to review before every stage transition.

No known critical issue should cross from DVT to PVT. No exceptions.

5 They build trust between R&D and NPI.

“Engineering and manufacturing speak different languages. NPI is the translator. If that bridge breaks, the whole thing breaks.”

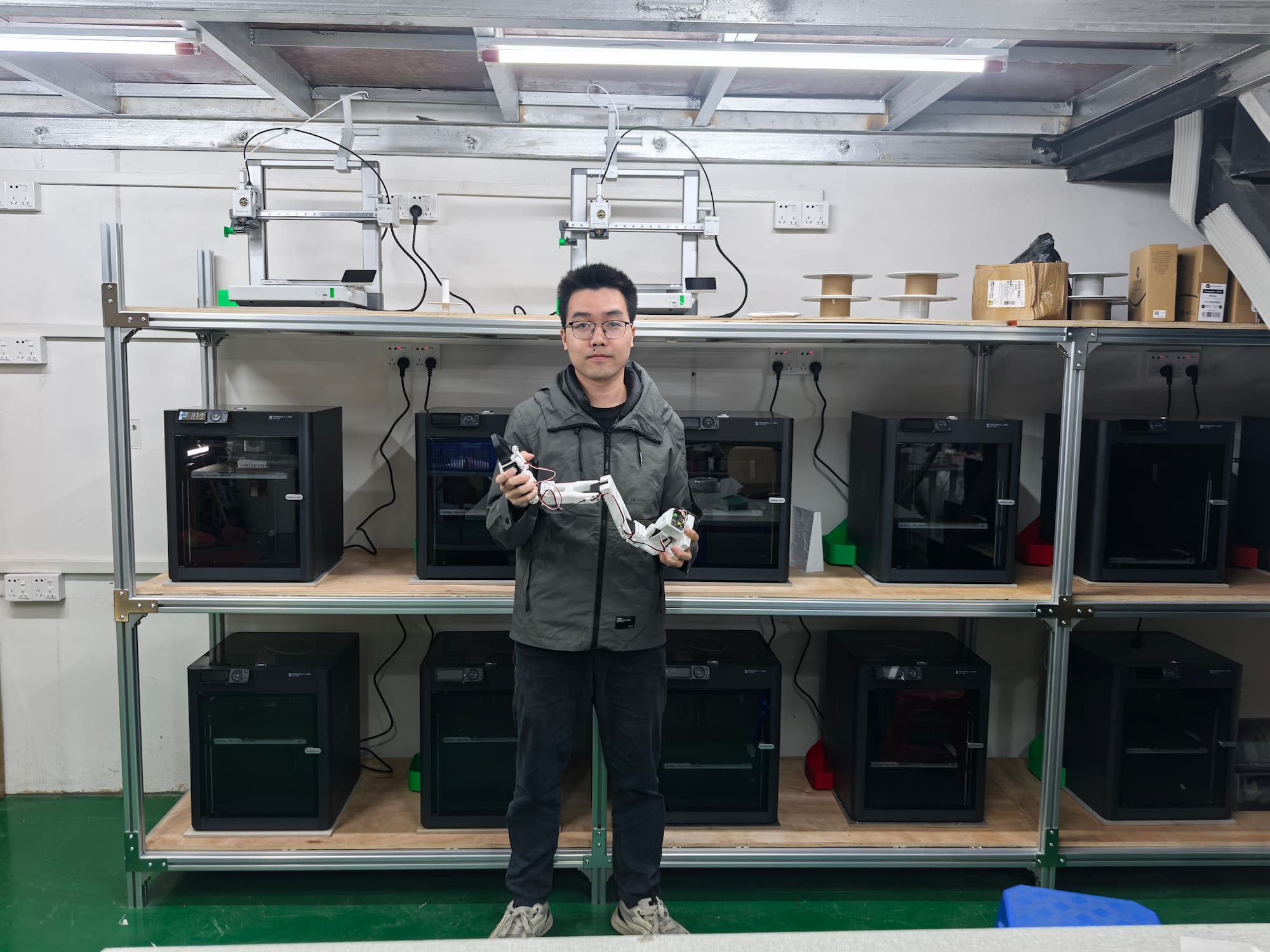

Why Carson Built His Own CNC and Pilot Line

One of the most surprising things about Carson’s team is that they’ve invested in their own CNC shop and pilot-scale test line.

“It wasn’t a strategy, it was survival.”

Early clients were mostly startups. They needed fast, iterative prototyping. But traditional factories wouldn’t cooperate without firm volume forecasts. After too many delays, Carson decided to build in-house.

Now, they can turn around small-batch mechanical samples in 1–2 days, with full control over scheduling, process tuning, and IP confidentiality.

“We only do one product in the workshop at a time,” he says. “That’s how we protect client privacy and flexibility.”

They Don’t Build Their Own Hardware And That’s the Point

Interestingly, Carson’s team has no plans to launch their own products.

“We want founders to trust that we’re here to help—not compete. That’s why we don’t do our own hardware. Instead, we’re building some general-purpose testing modules that can lower setup costs for others.”

What Overseas Teams Often Miss

Carson’s been working more and more with international startups lately, especially from the US. One thing he’s noticed:

“Overseas teams are often great at research and have clear product goals. But they’re slower to iterate. Chinese teams move fast and adapt quickly—but sometimes skip critical validation.”

His team adapts to both. With overseas clients, they emphasize clear planning and detailed feedback loops. With Chinese clients, they move fast, solve problems on the fly, and build in flexibility.

3 Things to Clarify Before You Build in China

For overseas founders looking to bring a smart hardware idea to China, Carson offers three critical questions to answer first:

1 What’s the core feature you can’t compromise on?

Defer the rest to later versions.

2 What’s your real cost ceiling for production?

Factor in testing, packaging, logistics—not just BOM.

3 Can your idea be built with existing supply chain technology?

If it needs custom processes or unproven suppliers, timeline and budget will both stretch.

A Different Kind of Shenzhen Supply Chain Team

Carson doesn’t call his team a factory. Or a design house. Or a trading company.

They’re just a group of engineers who love helping good hardware ideas become real.

“If you know what you want to build, we can help you figure out how to actually make it—step by step, and faster than you think.”